Automatic size changeover system for washing and drying systems

Downtime and productivity problems

It is well known that the productivity of a plant is given by the ratio of shift duration to the time during which the plant is actually producing within that shift.

In a perfect world these two items would coincide (I turn the plant on at the beginning of the shift and turn it off at the end of the shift) but the reality is a little different: there are in fact machine downtimes. We can divide them into two categories, the incidental (usually plant or machine failures on the same line) and what we call the “necessary” ones. The latter are nothing but downtime due to operations to adapt the plant to the format to be processed-in other words, to change-format. How can these downtimes be reduced?

For the first type (the incidentals), good preventive maintenance can help; in fact, it is well known that most equipment failures due to wear and tear are almost always predictable and solvable before they occur. Regarding the second one it can represent a good slice of the time-shift, in fact, it must be considered that for each change-over it can take on average 30 minutes for a specialized technician and if then there is the need to carry out more change-over the whole must be multiplied accordingly.

Innovative ‘Easy’ automatic format change system

“EASY” is the innovative system for automatic format change that allows a reduction in machine downtime of more than 90% compared to a conventional machine.

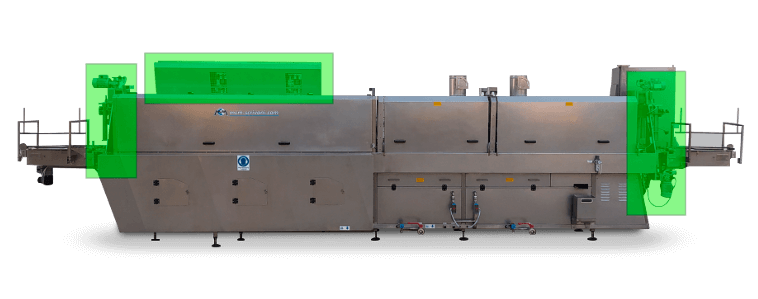

Machine with highlighted format change

Quick and easy format change

“EASY” is a system that allows our machines to perform format changeover autonomously in a maximum of 2 minutes and without the need for specialized personnel. And when we say “autonomously,” we mean that the operator simply has to select the desired format from a pre-set list on a touch-screen (estimated time for the operation 30 seconds), after which the machine will position all the guides and air blades by itself, adjust the temperature of the wash water (*) and the forward speed of the conveyor belt in about 2 minutes without the need for the presence of any operator.

This innovative system not only almost completely reduces machine downtime due to format changes, but also means that no operator is required for such operations, thereby achieving a double economic saving that can easily be estimated (e.g. 4 format changes/day X 240 working days/year = 960 format changes/year, i.e. at least 480 hours/year saved, in addition to freeing up valuable specialised resources to be employed in other tasks).

The time required to bring the flushing water to temperature is a function of the capacity of your thermal system.

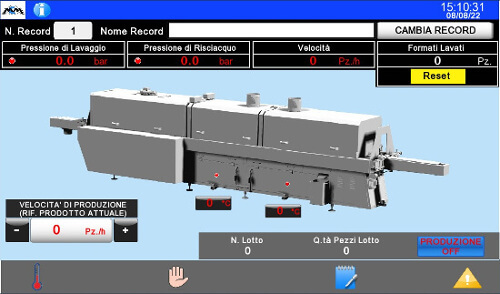

Access the list of formats

From the main screen, access the list of previously loaded formats by clicking on the ‘Change Record’ button.

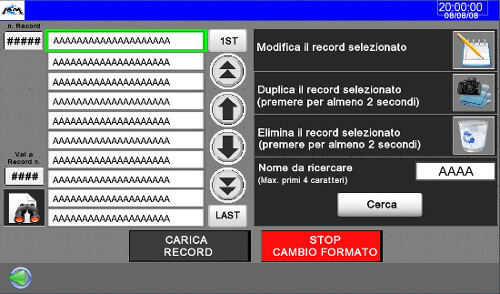

Select new format

To initiate the format change, simply select the new format from the list and click the ‘Load Record’ button.

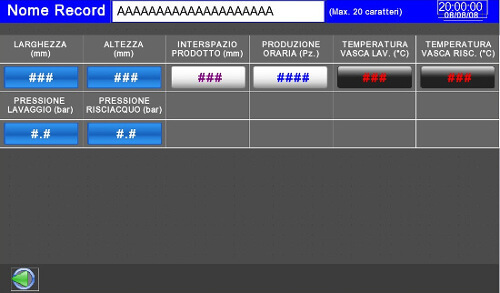

Add / Edit Format

At any time it will be possible to create a new format or view the parameters of previously entered formats and modify them.

Less time, more productivity

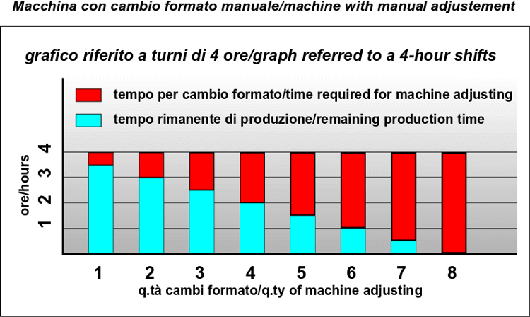

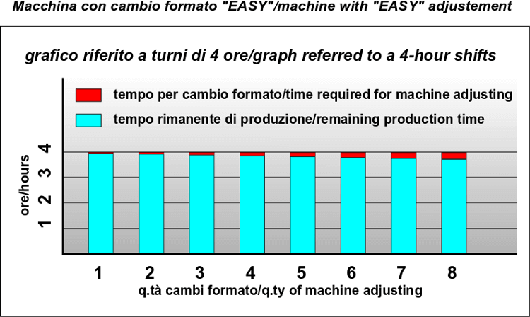

To make it clearer how considerable the savings that can be achieved with “EASY” are, we thought we would reproduce all that has been said so far in two simple graphs in which the part needed to change-format in a 4-hour shift is highlighted in red, and how much actual production time is left at the plant. The “EASY” system manages to be on average 15 times faster and, above all, enormously more accurate and repetitive than what a specialized technician can do. In practice, in the time it takes an operator to make a single format change, the “EASY” system could make up to 15 completely independently and all with the same accuracy.

System available for the following products

Washing

NETTUNO SERIES: Automatic machines for continuous washing only of food products packed in glass and thermoplastic jars and bottles, in metal cans, in thermoplastic trays and buckets and in multilayer aluminium bags.

Drying

EOLO SERIES: Automatic machines for continuous drying only of food products packed in glass and thermoplastic jars and bottles, in metal cans, in thermoplastic trays and buckets and in multilayer aluminium bags.

Washing and Drying

ATLAS SERIES: Combined automatic machines for continuous washing and drying of food products packaged in glass and thermoplastic jars and bottles, in metal cans, in thermoplastic tubs and buckets and in multilayer aluminium bags.